It is a key part of the heat treatment furnace, whether for case hardening, carbonitriding, quenching and hyperquenching, brazing, sintering, annealing (low temperature but also bright annealing on stainless steel), and other related industrial processes. The muffle is subjected to high levels of thermal, mechanical and chemical stress as a result of the active atmosphere.

We can offer you a replacement or repair, and we are able to reproduce any type of muffle made in boiler making, from the simplest to the most complex shapes.

Our sales, technical and administrative teams are on hand to provide you with the most suitable muffle for your furnace.

Other accessories

We have drawn on our years of experience and our knowledge of furnaces and their environment to provide you with :

- Turbines, we can offer to repair your motors or supply them as a complete package. There are standard products (furnace turbines compatible with T120/T80/T40 type furnaces, for example), but we can also make customised products.

- Cooling channel & siphons / oven outlet trap. Available in stainless steel or steel on request.

- Spare parts for gas generators (generator retorts, condensers) which can also be repaired.

- Seals for the connection flanges of your muffles. Injector augers.

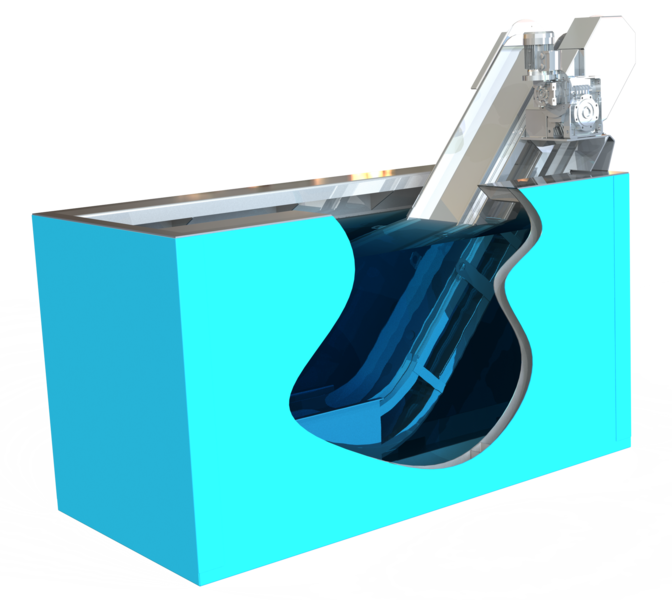

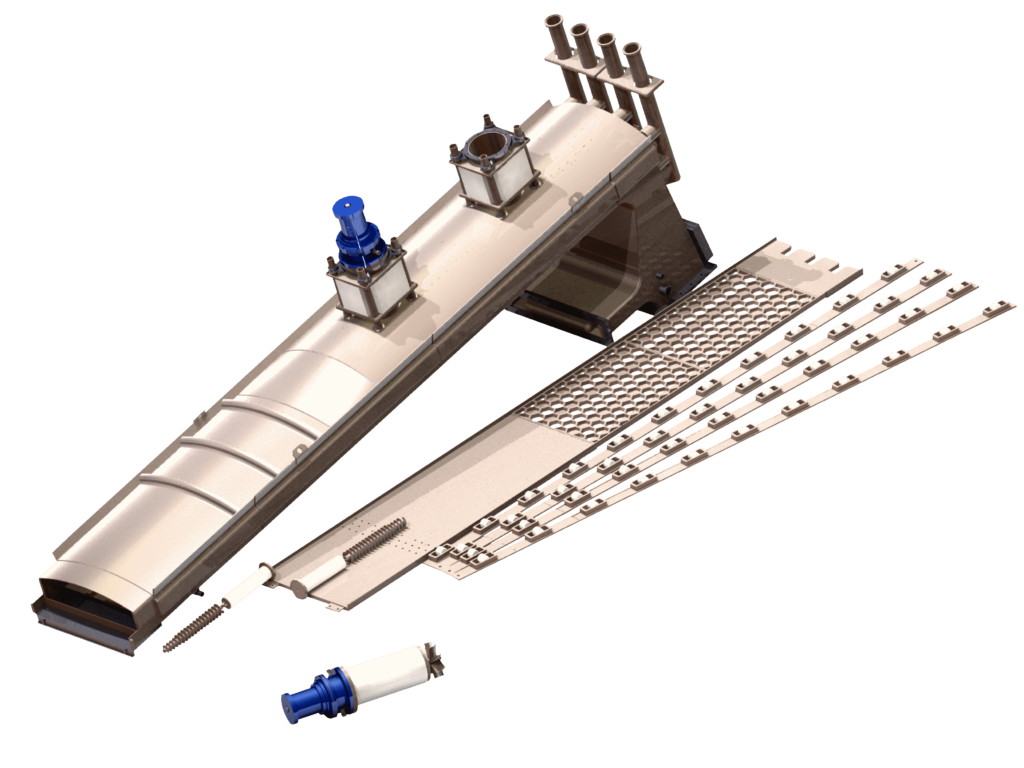

- Belts/quenching tank extractor/elevators integrated into the heat treatment line, based on a model or design to suit your environment.